JJ–LPK500 ફ્લો બેલેન્સ બેચર

અરજી

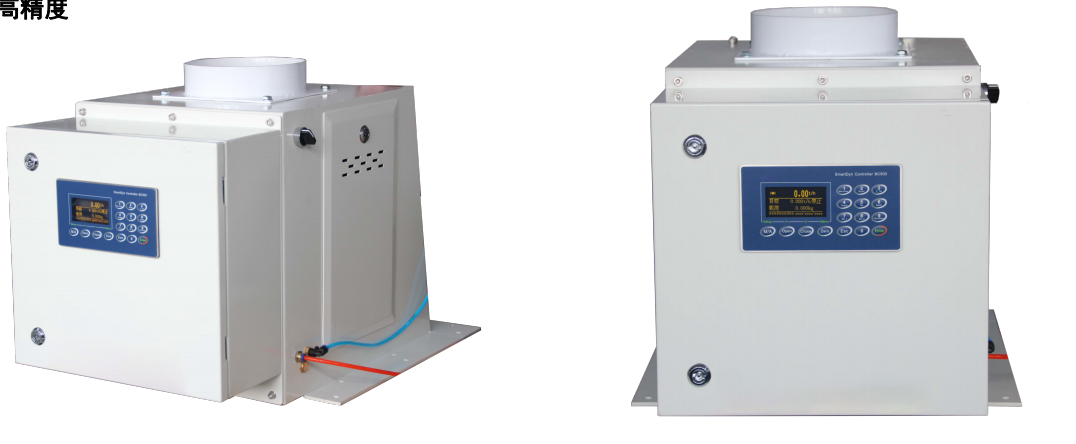

● ચોખા પ્રક્રિયા ઉદ્યોગમાં ચોખા અને ડાંગરનું મિશ્રણ; લોટ મિલોમાં ઘઉંનું મિશ્રણ; સામગ્રી પ્રવાહનું સતત ઓનલાઇન નિયંત્રણ.

● અન્ય ઉદ્યોગોમાં દાણાદાર સામગ્રીનો પ્રવાહ નિયંત્રણ.

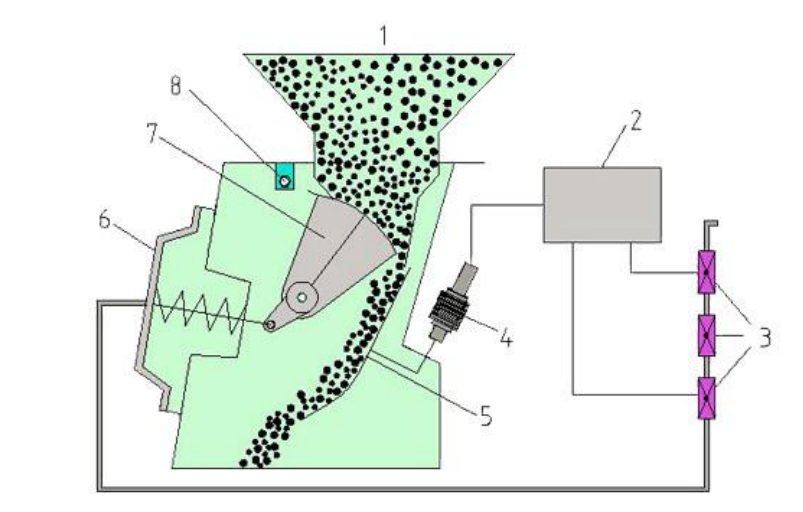

મુખ્ય માળખું

1. ફીડિંગ પોર્ટ 2. કંટ્રોલર 3. કંટ્રોલ વાલ્વ 4. લોડ સેલ 5. ઇમ્પેક્ટ પ્લેટ 6. ડાયાફ્રેમ સિલિન્ડર 7. ઘટકો આર્ક ગેટ 8. સ્ટોપર

લક્ષણો

● ઉચ્ચ-ચોકસાઇ નિયંત્રણ સાધન, વિભાજિત કેલિબ્રેશન, સામગ્રી લાક્ષણિકતા મેમરી કરેક્શન ટેકનોલોજી, ચોક્કસ પ્રવાહ માપન અને સમગ્ર શ્રેણી પર નિયંત્રણની ખાતરી કરવા માટે.

● બેચિંગ સિસ્ટમ વપરાશકર્તા દ્વારા નિર્ધારિત કુલ રકમ અને પ્રમાણ અનુસાર આપમેળે નિયંત્રિત અને ગોઠવી શકાય છે.

● RS485 અથવા DP (વૈકલ્પિક) સંચાર ઈન્ટરફેસ, રિમોટ કંટ્રોલ માટે ઉપલા કમ્પ્યુટર સાથે જોડાયેલ છે.

● સામગ્રીની અછત, સામગ્રીને અવરોધિત કરવા અને આર્ક ગેટની નિષ્ફળતા માટે સ્વચાલિત એલાર્મ.

● વાયુયુક્ત ડાયાફ્રેમ આર્ક-આકારના સામગ્રીના દરવાજાને ચલાવે છે, જે સામગ્રીને વેરહાઉસની બહાર વહેતી અટકાવવા અને માપન તત્વ અને નીચેના મિશ્રણ અને પરિવહન સાધનોને નુકસાન પહોંચાડવા માટે પાવર બંધ હોય ત્યારે સામગ્રીના દરવાજાને આપમેળે રીસેટ કરે છે અને બંધ કરે છે.

● જ્યારે એક સાધન નિષ્ફળ જાય અથવા સિલો સામગ્રીની બહાર હોય, ત્યારે બાકીના સાધનો આપમેળે બંધ થઈ જશે.

સ્પષ્ટીકરણ

| મોડલ | SY-LPK500-10F | SY-LPK500-40F | SY-LPK500-100F |

| નિયંત્રણ શ્રેણી (T/H) | 0.1-10 | 0.3-35 | 0.6-60 |

| પ્રવાહ નિયંત્રણ ચોકસાઈ | સેટ મૂલ્ય કરતાં ઓછું ±1% | ||

| સંચિત મર્યાદા શ્રેણી | 0~99999.9t | ||

| ઓપરેટિંગ તાપમાન | -20~50℃ | ||

| વીજ પુરવઠો | AC220V±10%50Hz | ||

| હવાનું દબાણ | 0.4Mpa | ||